1 / 20

Details

TypeProduction Lines

ConditionNew

Payment OptionCash or Installment

Description

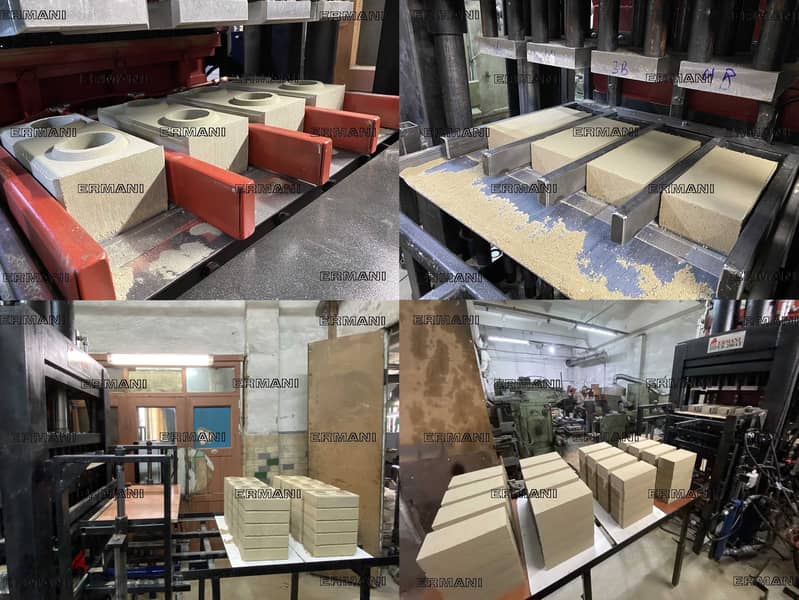

ERMANI hiper-200AT - a press for the production of building products.

We manufacture custom-made equipment for any customer request. Multimatrix system.

Create your own plant from a variety of products on one equipment.

The production Company ERMANI-COM offers you equipment (hyper press and vibropress) for the production of building bricks, other form of bricks, for example, LEGO-like brick, paving slabs, building blocks, curbs and other elements of building material.

You can use the following materials for pressing bricks: river and quarry sands, screenings from the mining of limestone (carbonate) rocks: shells,

Limestone, dolomites, travertine, marbles, calcareous (dolomite) crushed stone screenings, volcanic ash, and as well various screenings of soft rocks.

The prime cost of building material produced on this type of equipments is much lower than those that are produced by the other types of equipment. The binding material is the cement, which is sufficient in a 10% proportion for obtaining an excellent result in the maturation of bricks.

The one of kind equipment that gives the possibility of the brick form replacing to another product of another form (paving slabs, bricks of different forms) within 30-60 minutes, and also the possibility of adjustment of the product height in a range from 15 mm to 100 mm.

PRICES FROM THE MANUFACTURER, WE ARE WORKING DIRECTLY WITH THE CUSTOMERS.

All information on the equipment, characteristics, performance and composition of the mixture you can see on the manufacturer's website: www. ermani-press. com/en

Advantages of LEGO-like brick:

1) Exact dimensions regarding the length, width and height.

2) Ease and speed of laying due to the two round guide holes.

3) There is no need to hire a builder to lay bricks. Any person will be able to construct any building with the LEGO-like brick on the principle of the LEGO constructor for children.

4) The brick is put on the tile adhesive for outdoor work, but not on cement mortar.

5) The vertical canals of LEGO-like brick can be reinforced, in the process of building of the walls for the residential and other kind of sites, significantly increase their durability. This is especially important in the areas with an increased seismic activity.

6) The brick is formed in the working chamber of the machine; it can be easily removed with the hands and does not require a kiln roasting. Hence - its low cost.

The material for forming LEGO-like brick: sand (92-95%) and as a binder is used the cement (5-8%) .

Write.

Location

Egypt

Ad id 197696896

Report this ad

Listed by private user

ERMANI EQUIPMENT (for building materials)

Member since May 2023

See profile

Your safety matters to us!

- Only meet in public / crowded places for example metro stations and malls.

- Never go alone to meet a buyer / seller, always take someone with you.

- Check and inspect the product properly before purchasing it.

- Never pay anything in advance or transfer money before inspecting the product.